Minimizing Packaging EPR Fees

- Andrea Teslia

- Jan 16, 2024

- 4 min read

Extended Producer Responsibility (EPR) is not a new concept, it has existed since the 1990s for a variety of different consumer waste categories. EPR exists primarily as a result of the product's harmful impacts on the environment at its end-of-life, if not managed separately - like tires, thermometers, batteries, electronics, and the latest addition - packaging waste. To manage distinct waste streams typically requires specialized facilities, processes, and tools and; ultimately, investment.

When curbside recycling began in Canada in the 1980’s, the responsibility to recycle fell to municipalities. In recent years, the responsibility shifted to both municipalities and Producers, with the transition to full Producer responsibility being the final phase we find ourselves in now. This is a result of increased financial pressures to maintain, upgrade and operate the required infrastructure for successful recycling programs. For the remainder of the article, the EPR scheme referred to is Packaging and Printed Paper (PPP).

Why EPR?

Extended Producer Responsibility is a policy approach that shifts the responsibility for the cost of managing the obligated materials after a consumer has used them, from the municipal tax base to the Producer. A Producer is defined as either the brand holder, the first importer into the province, or the seller of the obligated material into the province – depending on the scenario at hand.

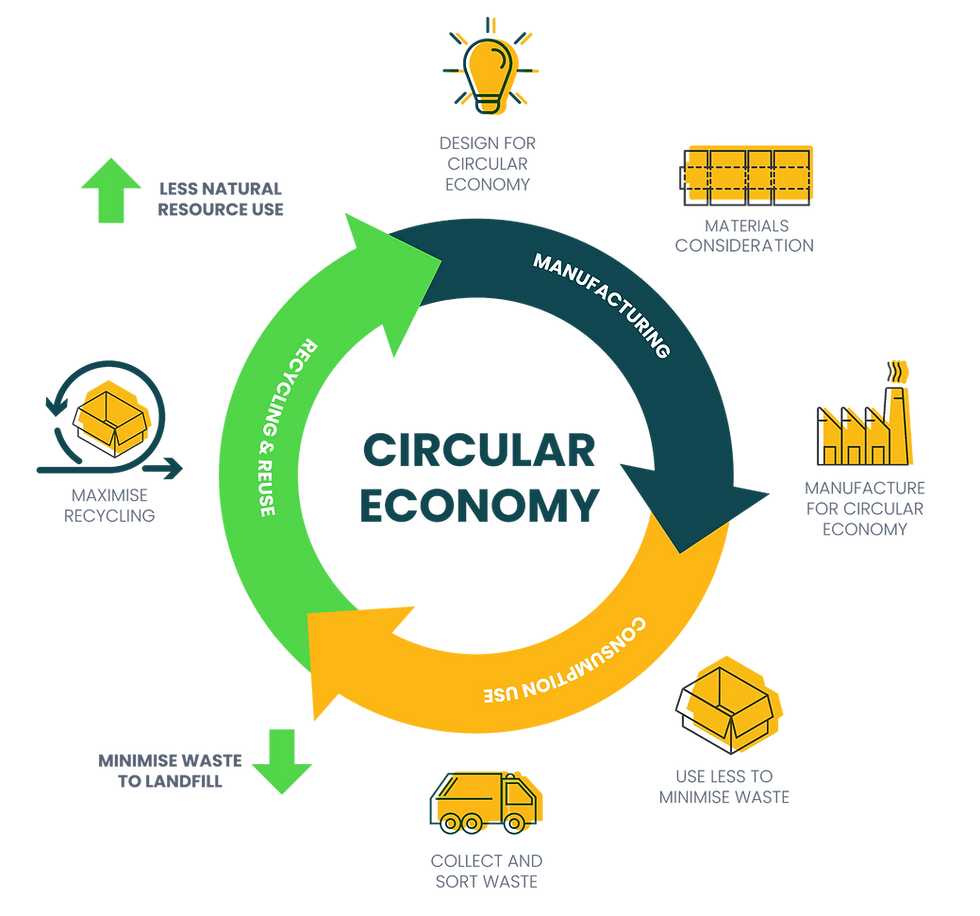

As Producers become increasingly aware of the extended cost of their packaging, they can seek to minimize this by considering a multitude of factors:

1. Material the obligated product is made of

Sometimes function comes before design, but where similar materials can be used for the same product consider more recyclable alternatives (which are often more economical).

Packaging departments exist for this purpose, as there is a cost-benefit analysis which needs to be done on all products. Scenario modelling which considers EPR fees can inform your company’s packaging strategy.

2. The environmental design of its packaging

Producers have begun to adopt the industry's Golden Design Rules, which aim to change how packaging is designed in the first place to keep it in the economy and out of the environment. The nine Golden Design Rules provide a clear framework that aims to drive innovation and scalable actions that will result in less plastic packaging overall and easier to recycle plastic packaging by 2025[i]. Less packaging = fewer EPR fees.

Eco-incentives are offered by some Producer Responsibility Organizations (PROs), which offer credits to Producers if certain packaging (re)designs are attained

For example, Éco-Enterprise Québec (ÉEQ) - Québec’s PRO, offers ecodesign credits up to $60,000 under four main themes: source reduction, procurement, recyclability, and communication

Québec, alongside France, has also implemented what has been termed a “bonus/malus” feebate program. This rewards (bonus) the use of certain materials, while penalizing (malus) others. Québec’s program rewards the use of post-consumer recycled (PCR) content, while penalizing the use of PVC and degradable plastics.

3. Supplier location

As mentioned above, there is a Producer hierarchy in place in each province which helps to determine who holds the responsibility to pay for obligated products. For most provinces, with the exception of Ontario and New Brunswick, the hierarchy is as follows:

Brand Owner unless non-resident

First supplier of PPP into [province]

Purchaser of PPP outside of [province] for use in [province]

Ontario and New Brunswick use a more simplified definition of responsibility:

Brand Owner/ Importer into [province] irrespective of provincial setup.

This becomes particularly relevant if a Producer is a reseller – or a company which sells another company’s products. If a reseller is selling products from another company that is not resident in [province] or Canada – then the reseller is obligated to cover the cost to recycle these products.

It’s no simple task, but resellers can look to implement procurement policies of their own which would compel out-of-province/country brand holders to

a. Assume responsibility for its packaging EPR fees and/or

b. Adhere to applicable eco-design practices for its packaging

The first step would be to understand which of a Producer’s suppliers are already registered within the respective provinces the company is obligated in.

4. Stakeholder objectives

This final factor is dependent on the Producer’s strategic direction. Does the organization align with any 3rd party climate-related targets, like the Canada Plastics Pact, or the United Nation’s Sustainable Development Goals (SDGs)? Are there any internal goals the organization has committed to achieve and track? Like being Climate Positive by… or Carbon Neutral by…

Company objectives like these are developed in part to position the company as stewards of the environment in the consumer’s mind; but they also provide a strategic framework by which a company can address sustainability challenges related to its industry.

When a company sets objectives like these, they need to be monitored on an ongoing basis. Whether it is for the company’s annual Sustainability Report or to receive third- party accreditation, verifiable data is required.

-

Minimizing EPR fees is no simple task, especially as other provinces implement Packaging and Printed Paper EPR programs of their own. The four ideas listed above do not apply to every organization, so take what you can for your next strategy meeting, as there are multiple departments which need to be consulted before a change can be made.

Ask us how Greenstreets can help

Comments